产品中心

T40H type manual regulating valve

Product description

T40H-10, T40H-16, T40H-25 manual regulating valve: suitable for steam or hot water pipelines with working pressure ≤1.6MPa and medium temperature ≤200℃ (and ≤2.5MPa, medium temperature≤350℃) for regulating flow.Rotate the handwheel clockwise to close the manual regulating valve. At this time, the stem drives the disc down until the two tapered sealing surfaces are in contact and the pipeline is closed tightly.

Product features:① Improve the heating and supply conditions: All branch lines and heat points that use manual regulating valves can adjust the flow rate according to the design working conditions to achieve good temperature working conditions. This kind of regulating valve has better regulating performance than gate valves and globe valves, and it has similar linear regulating performance.Therefore, the unevenness of heat and cold in various heating buildings has been effectively improved.② Energy saving: Due to temperature and pressure imbalance in the heat pipe network, the flow rate of some branches is too large, and the temperature of some buildings is too high. Users have to open windows to save energy.③Improve the hydraulic working conditions of the network management: The manual control valve can be controlled according to the rated flow rate, which reduces the flow rate of excessive operation of the network management, and improves the degree of deterioration of the original water working conditions to a certain extent.

Product performance parameters

Model number | PN | Working pressure/MPa | Applicable temperature/℃ | Applicable media |

T40H-10 | 10 | 1.0 | ≤200 | Water, steam |

T40H-16 | 16 | 1.6 | ||

T40H-25 | 25 | 2.5 |

Product parts and materials

Model number | Material | ||

Valve body, valve cover, packing gland, handwheel | Valve stem, valve disc sealing ring | Indicator plate, stem nut, nut sleeve | |

T40H-10 | Gray cast iron, (cast steel) | Stainless steel | Brass |

T40H-16 | |||

T40H-25 | |||

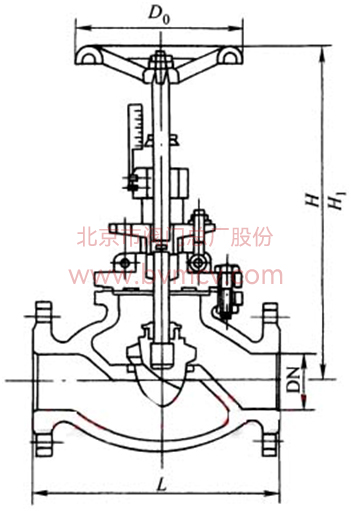

Product shape and structure size(mm)

DN | L | D | D1 | D2 | f | b | H | H1 | D0 | z×Φd | weight/kg |

250 | 730 | 395 | 350 | 320 | 3 | 28 | 914 | 1074 | 500 | 12×Φ22 | 327 |

300 | 850 | 445 | 400 | 370 | 4 | 28 | 914 | 1074 | 500 | 12×Φ22 | 422 |

350 | 980 | 505 | 460 | 430 | 4 | 30 | 968 | 1168 | 500 | 16×Φ22 | 610 |

400 | 991 | 565 | 515 | 482 | 4 | 32 | 968 | 1168 | 500 | 16×Φ26 | 750 |

450 | 1092 | 615 | 565 | 532 | 4 | 32 | 1100 | 1350 | 680 | 20×Φ26 | 999 |

500 | 1194 | 670 | 620 | 585 | 4 | 34 | 1100 | 1350 | 680 | 20×Φ26 | 999 |

DN | L | D | D1 | D2 | f | b | H | H1 | D0 | z×Φd | weight/kg |

15 | 130 | 95 | 65 | 47 | 2 | 14 | 160 | 172 | 65 | 4×Φ13.5 | 2.5 |

20 | 150 | 105 | 75 | 58 | 2 | 16 | 160 | 172 | 65 | 4×Φ13.5 | 3.5 |

25 | 160 | 115 | 85 | 68 | 2 | 16 | 182 | 195 | 80 | 4×Φ13.5 | 4.8 |

32 | 180 | 140 | 100 | 78 | 2 | 18 | 192 | 210 | 80 | 4×Φ13.5 | 7 |

40 | 200 | 150 | 110 | 88 | 3 | 18 | 250 | 273 | 120 | 4×Φ13.5 | 9.5 |

50 | 230 | 165 | 125 | 102 | 3 | 20 | 264 | 290 | 120 | 4×Φ17.5 | 13.5 |

65 | 290 | 185 | 145 | 122 | 3 | 20 | 380 | 426 | 200 | 4×Φ17.5 | 29 |

80 | 310 | 200 | 160 | 133 | 3 | 22 | 413 | 468 | 200 | 8×Φ17.5 | 35 |

100 | 350 | 220 | 180 | 158 | 3 | 24 | 466 | 530 | 240 | 8×Φ17.5 | 56 |

125 | 400 | 250 | 210 | 184 | 3 | 26 | 540 | 613 | 260 | 8×Φ17.5 | 79 |

150 | 480 | 285 | 240 | 212 | 3 | 26 | 623 | 698 | 360 | 8×Φ22 | 117 |

200 | 600 | 340 | 295 | 268 | 3 | 30 | 687 | 777 | 400 | 12×Φ22 | 185 |

250 | 730 | 395 | 350 | 320 | 3 | 30 | 940 | 1074 | 500 | 12×Φ22 | 327 |

300 | 850 | 445 | 460 | 430 | 4 | 30 | 940 | 1074 | 500 | 12×Φ22 | 422 |

DN | L | D | D1 | D2 | f | b | H | H1 | D0 | z×Φd | weight/kg |

15 | 130 | 95 | 65 | 47 | 2 | 16 | 160 | 172 | 65 | 4×Φ13.5 | 2.5 |

20 | 150 | 105 | 75 | 58 | 2 | 18 | 160 | 172 | 65 | 4×Φ13.5 | 3.5 |

25 | 160 | 115 | 85 | 68 | 2 | 18 | 182 | 195 | 80 | 4×Φ13.5 | 4.8 |

32 | 180 | 140 | 100 | 78 | 2 | 20 | 192 | 210 | 80 | 4×Φ13.5 | 7 |

40 | 200 | 150 | 110 | 88 | 3 | 20 | 250 | 273 | 120 | 4×Φ17.5 | 9.5 |

50 | 230 | 165 | 125 | 102 | 3 | 22 | 264 | 290 | 120 | 4×Φ17.5 | 13.5 |

65 | 290 | 185 | 145 | 122 | 3 | 24 | 380 | 426 | 200 | 8×Φ17.5 | 29 |

80 | 310 | 200 | 160 | 133 | 3 | 26 | 413 | 468 | 200 | 8×Φ17.5 | 35 |

100 | 350 | 235 | 190 | 158 | 3 | 28 | 466 | 530 | 240 | 8×Φ22 | 56 |

125 | 400 | 270 | 220 | 184 | 3 | 30 | 540 | 613 | 260 | 8×Φ26 | 79 |

150 | 480 | 300 | 250 | 212 | 3 | 34 | 623 | 698 | 360 | 8×Φ26 | 117 |

200 | 600 | 360 | 310 | 278 | 3 | 34 | 687 | 777 | 400 | 12×Φ26 | 185 |

Schematic diagram of product shape and structure size

联系我们

北京总部: 北京市大兴区庞各庄镇绿海路3号

生产基地: 河北省邯郸市成安县聚良大道北8号

南方区域: 18800004070

北方区域: 13811335563

防伪查询: 18811039510

邮箱: bvmcvv@163.com

Copyright: Beijing Valve General Factory Co., Ltd. 京ICP备08004565号-2

- 在线沟通

- 邮件联系

- 咨询电话 18800004070

- 咨询电话

- 返回顶部